Natural Disasters

Adaptable Temperature Control

Rapid Urbanization

Low Maintenance & Speed

Construction Efficiency

Prefabrication

High Building Material

Cost Competitive

High Wind Resistance

Growing Demand

Precision To 1 mm

WHAT IS

STEEL FRAMING?

Steel framing is the most advanced, economical and environmentally friendly and mistake free methods of construction. Steel is now the most common method of building non-residential buildings throughout Europe and the USA. The process is simple:

- Provide any architecture or building type

- Our engineering team creates CAD files

- Our engineers provide static calculations meeting or exceeding local standards

- Our state of the art machines “print” an error free facsimile of the approved design

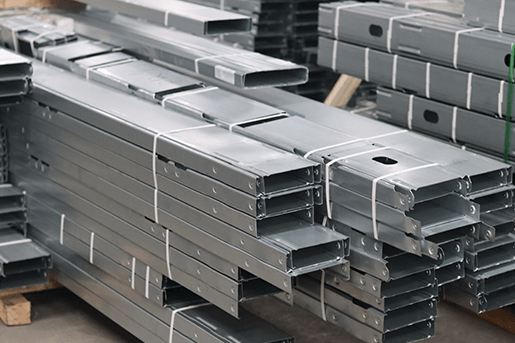

SYSTEM

ADVANTAGES

Steel Framing reduces risk and time from the project. VV has engineering and planning teams to help ensure the DESIGN, MANUFACTURE, and DEPLOYMENT phase are flawless – Techno Steel frame DESIGN and MANUFACTURE advantages include:

Fire Resistance

Can withstand temperatures up to 1000°C.

Termite & Pest Resistance

Steel is inorganic and impervious to insects.

Reduces skeleton build time dramatically (e.g., 9-story wood frame in 30 weeks vs. 16 weeks with LGS).

Lower risk profiles can reduce insurance premiums.

Insurance Benefits

Lower risk profiles can reduce insurance premiums.

Experience building to 9 stories

Withstands hurricane-force winds from 180-230 MPH.

G60-G90 zinc coatings protect against corrosion and moisture.

Engineered to resist earthquakes up to Category 9.

High Precision

CNC-formed profiles accurate to within 0.5 mm.

Structural Integrity

Suitable for buildings up to 11 stories with gauge 24-10 steel.

Reduces foundation requirements and structural loads.

Produces only 2% waste versus 20% in timber construction.

Environmentally Friendly

98% recyclable and significantly reduces carbon emissions.

Versatile Transportability

Components are easily shipped to remote or challenging sites.